Complex fabrics Kanaltex

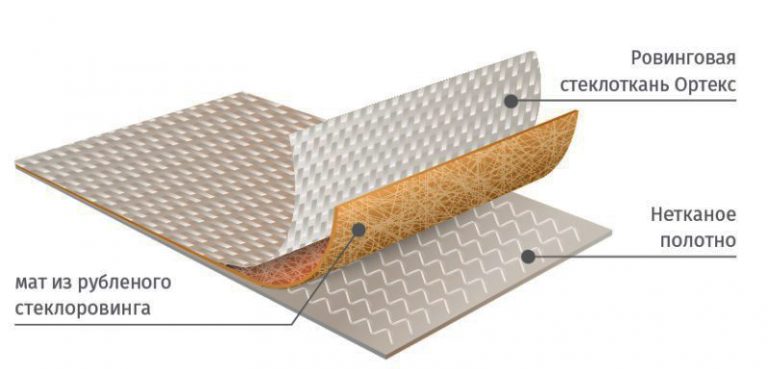

Complex fabric Kanaltex is a unique combination of two or more layers of different materials stitched with polyester thread:

- fiberglass fabric Ortex

- evenly distributed chopped fiberglass (fiberglass nonwoven)

- polyester nonwoven fabric

Complex fabrics Kanaltex increase the strength characteristics of composite materials and products based on them, and also have excellent corrosion resistance. They combine maximum strength in the orthogonal direction (radial and longitudinal) and multilateral strength. Complex fabrics Kanaltex provide flexibility of the liner during pulling and withstand all hydrodynamic and static loads that influence on the liner during operation.

By combining different layers of Kanaltex composite fiberglass fabrics, a large number of production options are possible. The equipment allows the production of complex fiberglass fabric with a density of 150 g / m² and a width of up to 4 meters. We also offer an individual solution for each client and are ready to participate in the research and development of new combinations.

- Variable structure (density, thickness, stitching)

- Individual packaging according to customer specification

- High strength with small thickness for small diameters

- Material width up to 4 m

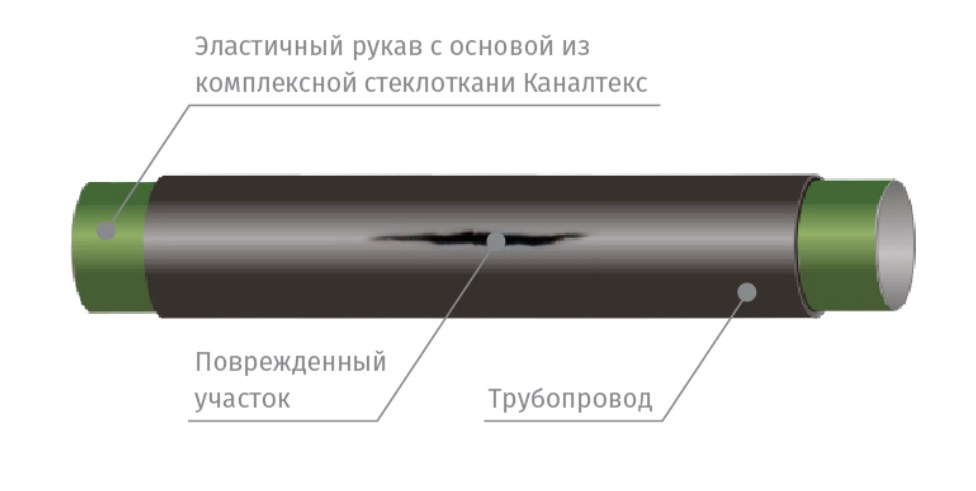

Complex fabrics Kanaltex are widely used in the production of liners for the rehabilitation of pipelines. During trenchless rehabilitation a new pipe is formed from the resin-impregnated and cured liner inside the repair section of the pipeline, which has its own bearing capacity. The design of the complex ensures the elasticity of the liner before curing and its mechanical properties after hardening. The presence of a nonwoven material increases the resistance of the liner to hydrodynamic loads when cleaning with water under high pressure is carried out.

Complex fabrics Kanaltex are widely used in the production of liners for the rehabilitation of pipelines. During trenchless rehabilitation a new pipe is formed from the resin-impregnated and cured liner inside the repair section of the pipeline, which has its own bearing capacity. The design of the complex ensures the elasticity of the liner before curing and its mechanical properties after hardening. The presence of a nonwoven material increases the resistance of the liner to hydrodynamic loads when cleaning with water under high pressure is carried out.

The fiberglass liner is a complex multilayer structure, which includes complex, multi-axial fiberglass fabrics and non-woven material, as well as protective films. The liner is pre-impregnated with resin (polyester, epoxy or vinyl ether) in the factory with strict adherence to qualitative and quantitative characteristics. Fiberglass liner is designed for overhaul (rehabilitation) of sewer collectors with a diameter of 150 to 1500 mm. Curing of the liner takes place directly in the pipe using UV radiation. Rehabilitation work is carried out at any time of the year, the speed of work is at least 100 linear meters per day.