Geogrids

Geogrids are a material made of fiberglass, polyester, basalt or carbon fiber. They are designed to reinforce various structural layers of road.

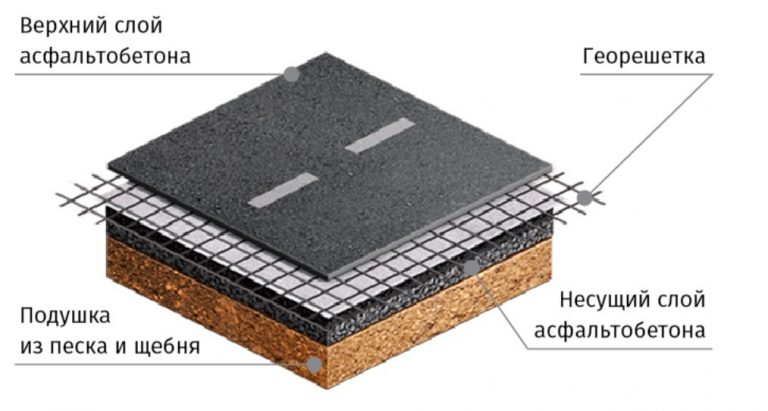

The traffic intensity is growing, thus increasing dynamic loads. Washboard waves, ruts and cracks occur on the pavement under the influence of temperature fluctuations, vehicle weight, acceleration and braking. Unreinforced asphalt concrete is not able to cope with high load points, so the main task of the reinforcing geogrid is to take over the voltage and redistribute it all the way. Due to this, it is possible to avoid the appearance of cracks, ruts, waves and increase the maintenance period of the road.

It is necessary to use a fiberglass, basalt or carbon geogrid for reinforcing of the asphalt concrete layer. Geogrids are impregnated with a polymer modified bitumen composition, and this provides good adhesion to the base layer of the asphalt concrete pavement. Bautex offers an exclusive product – a geogrid with a closed cell GL – the cell is filled with staple fiber. By filling the cell, the adhesion area increases with a bottom layer of the asphalt concrete pavement.The geogrid does not work as a separation layer, but tightly bonds the upper and lower parts of the asphalt concrete pavement. Good traction gives high pavement resistance to shear loads.

A closed cell provides several other benefits:

- No additional anchoring required

- It does not stick to the wheels of equipment, does not peel off from the bitumen layer, therefore there are no problems for equipment movement over the grid

- Saves time and money, as no additional sand layer is required for the paver passing

- Reduces the consumption of bitumen emulsion in contrast to the use of geogrids with non-impregnated textiles. This happens due to the fact that the geogrid, including filled cells, is already saturated with bitumen composition

- Reduces the time required for laying the road surface.

Earthworks also need reinforcement. Reinforcing grid made of polyester fibers is designed for reinforcing of soil structures at the base of the road and additional layers, retaining structures and steep slopes stabilization.

Polyester fibers are resistant to moisture, microorganisms and aggressive chemical environment (acids and alkalis). Geogrids for soil stabilization should be impregnated with pvc-plastisol, giving them extra protection.

Depending on the particular design of the road, the tensile strength, the impregnation type, the cell size and the width of the roll can vary.

- Shortest delivery time for non-standard custom orders

- Exclusive material – closed cell grid

- Our company is open to new projects, experiments and research.

- Customer focus

- Competitive price

- Modern European equipment

- Compliance with the declared technical parameters

Geogrids are made as two superimposed roving systems located in the longitudinal and transverse directions and fixed together with a stitching yarn. The material is impregnated with a polymer modified bitumen binder or PVC plastisol.

Use of geogrids for reinforcing of asphalt concrete pavement: before laying, the surface of the lower asphalt layer should be cleaned and treated with bitumen emulsion, then the geogrid is laid over the entire prepared area and fixed with anchors; in case of the geogrid with a closed cell, anchoring is not required.

It is necessary to apply bitumen on the edges of the laid material next to the curb stone or along the edge of the roadway. The top layer of the asphalt concrete mixture should completely cover the geogrid. Further, the layer is compacted by means of the road-roller.

It is necessary to apply bitumen on the edges of the laid material next to the curb stone or along the edge of the roadway. The top layer of the asphalt concrete mixture should completely cover the geogrid. Further, the layer is compacted by means of the road-roller.

Polyester geogrid for reinforcing of soil structures has a wider scope of application. This material performs a reinforcing function of the base and additional layers of pavement. The material is used in crushed stone, sand or soil. The soil base or additional sand layer must be leveled and compacted before application of the mesh. The material is rolled over the surface with a slight tension, if necessary and fixed with anchors. Next, the coarse grain material is measured off onto the base with required thickness and compaction of the layer according to the project. On slopes and artificial embankments, the polyester grid performs the function of the soil layers reinforcement prone to erosion. Reinforcement of the slopes is carried out in Spring. The material is laid on the soil cleared of stones and debris and fixed with special anchors. The roots of the sprouted grass further hold the soil.

The service life of the pavement can be increased when standards for the use of geogrids are followed. To achieve the best results, our company strongly recommends not to install the geogrid during heavy rainfall and snow, as well as during freezing temperatures.

Fiberglass and basalt geogrids are used in road construction as a reinforcing layer of the asphalt concrete layer. Geogrid of high strength polyester fibers is designed to reinforce earth structures.

Its use is necessary in construction and reconstruction of steep slopes for the reinforcement of layers of soft soil. Besides the highways, geogrids with increased tensile strength are used in the construction of the airfield runways. In this case we recommend using carbon fiber geogrid. The requirements of airport pavements are very high, because the runways are subject to temperature fluctuations and intense loads.

Carbon fiber has several advantages over other materials:

- Elongation less than 2%

- High resistance to high dynamic loads and vibrations

- Light weight

- Durability

The cost of this material is undoubtedly high, but it is justified. The use of carbon geogrid increases the time between refurbishment. This ensures uninterrupted operation of the airport, which does not require frequent and costly repairs of runways, which significantly saves money. It should be noted the quality of the runway pavement, on which the safety of air transport directly depends.

Airports

Roads

and motorways

Reinforcement

of earthworks

Customized

solutions

- Resistance to deformation at high loads and at sudden temperature changes

- High point load protection

- The use of geogrid reduces the amount of repairs and maintenance of runways

- Prevents pavement cracking

- Slows down the rutting process

- Extends the service life of asphalt concrete pavement

- Soil stabilization

- Prevention of erosion on slopes, trenches, walls

- It increases the bearing capacity of the base, when arranging road embankments on weak bases

- Production of geogrids from any material presented

- Tensile strength from 10 to 200 kN and more

- Roll width 1.0 to 5.4 m

- Cell size 20 to 50 mm